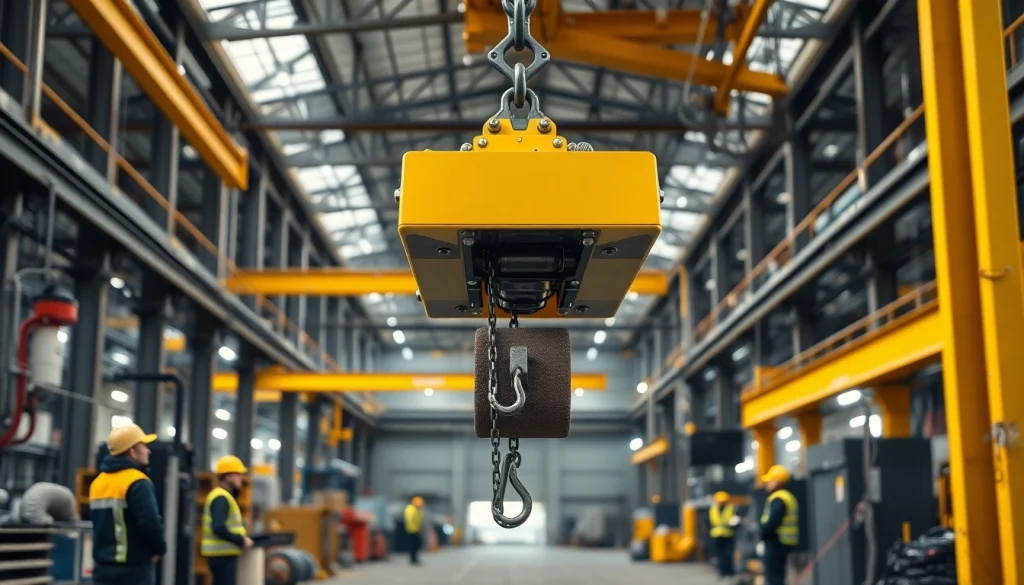

Understanding Electric Chain Hoist Cranes

The electric chain hoist crane is an essential piece of equipment in modern industrial settings, offering an efficient solution for lifting heavy loads with precision and ease. This advanced lifting tool combines the mechanical reliability of chain hoists with the power and convenience of electric motors, making it a popular choice across various applications. With the growing demand for automation and efficiency in industries, understanding the nuances of electric chain hoists becomes crucial for optimizing operational workflows and enhancing safety measures. When exploring options, electric chain hoist crane provides comprehensive insights into the lifting solutions available.

What Is an Electric Chain Hoist Crane?

An electric chain hoist crane is a type of material handling equipment that employs a motorized hoist to lift and lower loads through a chain system. Unlike manual chain hoists, which rely on physical effort to operate, electric chain hoists utilize electric power to facilitate lifting, making them ideal for high-frequency applications and heavy loads. Typically mounted on overhead systems or used with trolleys, they provide a vertical lifting motion that is essential for many industrial tasks.

Key Features and Benefits of Electric Chain Hoists

- Efficiency: Electric chain hoists allow for quick and reliable lifting, reducing the time required to move heavy materials.

- Ease of Use: With simple controls and user-friendly interfaces, operators can easily manage lifting operations without extensive training.

- Safety: Modern electric chain hoists include advanced safety features such as overload protection and emergency stop functions, minimizing risk during operation.

- Customization: Available in various capacities and configurations, electric chain hoists can be tailored to meet specific operational needs.

- Durability: Built from robust materials, electric chain hoists are designed to withstand demanding industrial environments, ensuring long-term performance.

Common Applications of Electric Chain Hoists in Industry

Electric chain hoists are widely used in numerous industries, including:

- Construction: Essential for lifting heavy materials such as steel beams and concrete blocks.

- Manufacturing: Employed in assembly lines for moving parts and finished products efficiently.

- Aerospace: Utilized for assembling and lifting aircraft components with precision.

- Warehouse Operations: Ideal for facilitating quick loading and unloading of goods, enhancing productivity.

- Maintenance and Repair: Commonly used for lifting machinery and vehicles for servicing.

Choosing the Right Electric Chain Hoist Crane

Factors to Consider When Selecting a Hoist

Selecting the appropriate electric chain hoist crane requires careful consideration of various factors to ensure optimal performance and safety. Key aspects include load capacity, environment, frequency of use, and operational space. Understanding the specific lifting requirements ahead of time will help in choosing a hoist that meets both safety standards and operational needs.

Capacity and Specifications: Finding Your Fit

The capacity of electric chain hoists varies widely, so it’s crucial to select one that can handle the intended loads effectively. Common capacities range from 1/8 ton to 5 tons or more. Operators should assess the weight of the heaviest load they plan to lift and ensure the hoist’s specifications support that weight, considering factors like lift height and speed.

Comparing Electric Chain Hoists to Other Lifting Solutions

When evaluating different lifting solutions, it’s essential to compare electric chain hoists to alternatives such as manual chain hoists, pneumatic hoists, and electric cable hoists. Each option has unique advantages and disadvantages:

- Manual Chain Hoists: Suitable for lower frequency and smaller loads, but require more physical effort.

- Pneumatic Hoists: Great for environments where electricity isn’t feasible, but less efficient for heavier loads.

- Electric Cable Hoists: Use a cable instead of a chain, suitable for different lifting needs but can be more expensive.

Safety Standards and Best Practices

Understanding Safety Regulations for Cranes

Compliance with safety regulations is paramount when operating electric chain hoists. OSHA standards, ANSI guidelines, and manufacturer recommendations should guide the safe use of hoisting equipment. Operators must regularly verify that equipment meets safety requirements to prevent accidents and injuries.

Best Practices for Operating Electric Chain Hoists

To ensure safe operation of electric chain hoists, follow these best practices:

- Conduct regular inspections and maintenance checks.

- Train operators thoroughly in safety and operational procedures.

- Implement load limits and never exceed the rated capacity.

- Utilize proper lifting techniques and avoid obstructions in the lift path.

- Have emergency protocols in place and ensure all operators are familiar with them.

Common Safety Pitfalls and How to Avoid Them

Several safety pitfalls can undermine the effectiveness of electric chain hoists, including:

- Overloading: Exceeding the hoist’s capacity can lead to mechanical failure and accidents. Always adhere to load ratings.

- Improper Use: Using the hoist for unintended applications can cause damage or injury. Ensure operators understand the specific purpose of the hoist.

- Neglecting Maintenance: Failing to perform routine checks can lead to equipment malfunctions. Schedule regular maintenance to keep equipment in top condition.

Maintenance and Troubleshooting

Routine Maintenance for Electric Chain Hoists

Maintaining electric chain hoists is vital for ensuring longevity and reliability. Key maintenance tasks include:

- Inspecting electrical connections for wear or damage.

- Lubricating moving parts to minimize friction and wear.

- Checking the chain for elongation and any signs of wear.

- Testing safety mechanisms regularly to confirm they function correctly.

Identifying Common Issues and Solutions

As with any machinery, electric chain hoists can experience issues. Some common problems include:

- Motor Failure: Can often be attributed to electrical issues. Regular inspections can help identify problems before they lead to failure.

- Chain Slippage: Indicates potential wear or incorrect tension. Immediate attention is required to prevent accidents.

- Control Malfunctions: Often stem from wear in switches or wiring. Troubleshoot by checking for visible damage and ensuring connections are secure.

When to Seek Professional Help

If problems persist despite routine maintenance efforts, it is advisable to seek professional assistance. Qualified technicians can perform thorough diagnostics and repairs, ensuring the equipment is safe to operate.

The Future of Electric Chain Hoist Cranes in 2025

Emerging Technologies in Hoisting Equipment

The hoisting equipment industry is witnessing significant advancements, with technologies such as IoT integration, automated controls, and smart sensors becoming increasingly prevalent. These technologies enable real-time monitoring of hoist performance, predictive maintenance, and enhanced safety measures.

Trends Impacting Industrial Lifting Solutions

As industries evolve, several trends are shaping the future of electric chain hoists:

- Automation: The push for automation is leading to more sophisticated hoisting technologies that integrate seamlessly into production lines.

- Sustainability: With a growing focus on eco-friendly practices, manufacturers are developing electric hoists with energy-efficient features.

- Customization: There is an increasing demand for customizable solutions that cater to specific industry requirements.

Sustainability Considerations for Modern Hoists

Sustainability is becoming a central concern in the design and operation of electric chain hoists. Innovations such as energy recovery systems, lightweight materials, and recyclable components are being implemented to reduce the environmental footprint of lifting equipment. Companies are encouraged to consider sustainability when selecting and operating hoisting solutions to align with global sustainability goals.